Electromagnetic Compatibility (EMC)

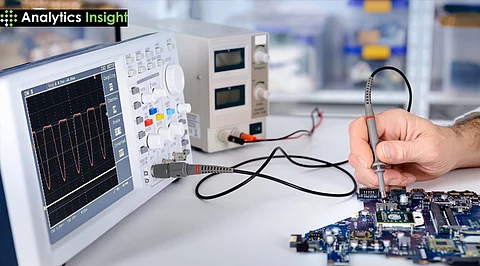

What is Electromagnetic Compatibility (EMC) ?

Electromagnetic Compatibility (EMC) refers to an electronic device’s capability to operate effectively within its environment without disrupting or being disrupted by other equipment through electromagnetic interference (EMI). It focuses on limiting unwanted emissions and enhancing immunity to external interference. EMC ensures seamless operation of multiple devices in shared environments like hospitals, factories, and airplanes.

Types of Electromagnetic Compatibility (EMC)

1. Emission and Immunity (Susceptibility)

Emission:

The generation and release of electromagnetic energy from a device into the environment. Emissions can be:

Radiated Emissions: Electromagnetic energy emitted through the air.

Conducted Emissions: Electromagnetic energy transmitted through cables or other conductors.

Immunity (Susceptibility):

The ability of a device to function properly in the presence of electromagnetic disturbances. Immunity can be tested for:

Radiated Immunity: Resistance to electromagnetic energy received through the air.

Conducted Immunity: Resistance to disturbances received through cables or conductors.

2. Types by Coupling Mechanism

Radiated EMC:

Concerns electromagnetic energy that travels through space (air) and can cause interference or be susceptible to it.

Conducted EMC:

Involves electromagnetic energy that travels along conductors such as wires, cables, or circuit traces.

Electrostatic Discharge (ESD):

Sudden transfers of static electricity that can disrupt or damage electronic equipment.

3. EMC Phenomena and Testing Types

Radiated Emissions Tests: Measure unwanted electromagnetic energy emitted into the environment.

Conducted Emissions Tests: Assess electromagnetic energy transmitted through power or signal lines.

Radiated Immunity Tests: Evaluate a device's resistance to electromagnetic fields from external sources.

Conducted Immunity Tests: Test resistance to disturbances conducted through cables.

Magnetic Field Immunity Tests: Assess performance against magnetic field disturbances.

Flicker and Harmonics Tests: Evaluate effects like voltage fluctuations and waveform distortion.

4. Standards and Sectors

Military and Civil Requirements:

Specific standards and test methods for emissions and immunity, including:

Conducted and radiated emissions/immunity for power, interconnection, and antenna cables.

Susceptibility to magnetic and electric fields, ground impedance coupling, and more.

Importance of Electromagnetic Compatibility (EMC)

Prevents Interference Between Devices

EMC ensures that electronic devices can operate in proximity without causing or suffering from electromagnetic interference. Without EMC, devices could disrupt each other’s operation, leading to malfunctions, data loss, or even physical damage-especially in environments with many electronic systems, such as hospitals, factories, or data centers.

Ensures Reliable and Safe Operation

By complying with EMC standards, devices are more likely to function correctly in their intended environments. This is critical for sensitive equipment like medical devices, industrial machinery, and navigation systems, where interference could compromise safety or lead to operational failures.

Compliance with Regulations

Many countries and regions require electronic devices to meet specific EMC standards before they can be marketed or used. Compliance is enforced by agencies such as the FCC in the United States and through EU directives in Europe. Meeting these standards is not only a legal requirement but also a mark of product quality and reliability.

Enhances Product Reliability and Brand Reputation

EMC testing identifies and addresses potential interference issues during product development, leading to more robust and reliable products. This reduces warranty claims, increases customer satisfaction, and strengthens brand reputation.

Reduces Operational Disruptions and Service Costs

Devices that do not meet EMC standards may cause or be affected by interference, resulting in costly recalls, repairs, or operational downtime. Early EMC testing helps avoid these issues, lowers long-term service costs, and speeds up time to market by catching problems before products are released.

Protects Sensitive and Critical Infrastructure

In environments like hospitals or cloud data centers, EMC is vital to ensure that critical systems-such as heart monitors, MRI machines, or servers-are not disrupted by electromagnetic emissions from nearby devices, safeguarding both data integrity and human safety.

Supports the Advancement of Technology

As electronic devices become more prevalent and complex, the importance of EMC continues to grow. It is a fundamental discipline that enables the safe coexistence of diverse technologies, supporting innovation and the expansion of modern electronic systems.

Use cases of Electromagnetic Compatibility (EMC)

Consumer Electronics (Smartphones, Tablets, Laptops)

Manufacturers like Apple rigorously test devices such as iPhones for EMC compliance to minimize interference and ensure performance. Techniques include shielding, optimized PCB layouts, and lighting integrity analysis, allowing multiple devices to coexist without disruption.

Automotive Industry

With the rise of electric vehicles (EVs) and autonomous driving, automotive manufacturers (e.g., Tesla) integrate EMC strategies such as shielding sensitive electronics, robust grounding, and careful sensor integration. This ensures that high-voltage systems and communication networks in vehicles do not interfere with each other, maintaining safety and reliability.

Medical Equipment

Companies like Medtronic implement strict EMC measures in devices such as pacemakers and implantable medical equipment. Special shielding, isolation, and rigorous testing are used to prevent electromagnetic interference that could compromise patient safety or device functionality.

Aerospace and Defense

Aerospace leaders like Boeing and Airbus apply advanced EMC techniques to protect avionics, communication, and radar systems from electromagnetic disturbances. This involves extensive shielding, component selection, and compliance with stringent aerospace EMC standards to ensure reliable operation in harsh environments.

Wireless Technology and Communications

The proliferation of 5G, IoT, and wireless charging introduces new EMC challenges. Companies like Qualcomm use advanced modeling and simulation tools to optimize chip and antenna designs, minimizing interference and ensuring reliable operation in crowded wireless environments.

Data Centers and Server Rooms

Tech giants such as Google and Amazon employ EMC measures like server shielding, proper grounding, and cable management to prevent electromagnetic interference that could disrupt data processing and storage operations.

Renewable Energy Systems

Providers like Siemens and Vestas use EMC strategies in wind turbines and solar panels to prevent electromagnetic interference from affecting grid stability and equipment reliability. Shielding and grounding techniques are essential for uninterrupted operation.

Railways and Transport

Companies such as Bombardier and Siemens incorporate EMC into train and signaling system designs. Proper shielding and grounding prevent interference that could impact communication and safety-critical equipment on rail networks.

Oil and Gas Industry

EMC is crucial for reliable operation of electrical equipment used in exploration, drilling, and extraction. Companies like Schlumberger use shielding, grounding, and EMC-based design to ensure performance under harsh electrical conditions.

Entertainment and Broadcasting

Studios and broadcasters (e.g., Dolby Laboratories) implement EMC measures in audio and video equipment to maintain signal fidelity and reduce interference, ensuring high-quality entertainment experiences.

FAQs of Electromagnetic Compatibility (EMC)

What is Electromagnetic Compatibility (EMC)?

EMC is the ability of an electrical or electronic device to operate correctly in its electromagnetic environment without causing or suffering from electromagnetic interference (EMI). This means the device does not disrupt other equipment and is not disrupted by them.

Why is EMC important in product design?

EMC is crucial to ensure that products function normally in complex electromagnetic environments, avoid performance degradation or failure due to interference, and do not generate harmful EMI that could affect other systems. It also helps products comply with legal standards, reducing the risk of recalls or penalties.

What is EMC testing?

EMC testing measures a device’s emissions (how much electromagnetic energy it emits) and immunity (how well it resists external EMI). Devices are tested in specialized environments to ensure they meet regulatory standards. Passing EMC tests is required for market approval in many regions.

What happens if a product fails EMC testing?

If a device fails EMC testing, it must be redesigned to address the issues-this could involve adding shielding, improving filtering, or redesigning circuits. The product is retested until it meets the required standards.

Why do regulations require EMC compliance?

EMC regulations protect critical infrastructure, ensure product reliability, and prevent disruptions in environments with many electronic devices (e.g., hospitals, airports). Compliance is mandatory in many industries, including medical, automotive, and aerospace.

Can you give an example of EMC in everyday life?

A modern smartphone is designed to function without interfering with nearby devices (like radios or pacemakers) and to remain unaffected by their electromagnetic emissions.

What documentation is needed for EMC compliance?

Manufacturers must provide test reports from accredited labs showing the device passed all required EMC tests. This documentation is necessary for regulatory approval and market access.

How has EMC awareness evolved?

EMC has become increasingly important as the number and complexity of electronic devices have grown, especially in sectors where interference can have critical consequences, such as healthcare, defense, and transportation.

Join our WhatsApp Channel to get the latest news, exclusives and videos on WhatsApp

.png)