Warehouse management is about optimising and controlling the operations and storage of the warehouse products right from the moment the inventory enters the facility until it is sold, becomes obsolete, consumed, or moved to another place.

On the other hand, a more discrete explanation of warehouse management available on the research gate says, "Analogues to production management, the warehouse management's objective is to coordinate all warehouse processes and activities efficiently and effectively. Warehouse management includes all planning and control procedures to operate the warehouse. Planning and control are concerned with managing the ongoing activities of the operations to satisfy customer demand. The primary purpose of planning and management is to ensure that operations run effectively and produce products and services as they should."

Technology plays a crucial role in shaping a business and managing a warehouse. Let's see which technologies can be adapted to contain a warehouse.

Industries around the world are embracing modern technologies like the internet of things (IoT), artificial intelligence (AI), machine learning (ML), cloud computing, etc., in the daily functioning of businesses. In the entire process, two important things occur that are innovation and disruption. Therefore, disruptive technology is the technological innovation that penetrates into the existing market and causes disruption there. Smart warehouses are the product of disruptive technologies like IoT and ML.

Warehouses are crucial in any supply-chain facilitating storage of goods till they get dispatched at a target location. Smart warehouse management system (WMS), an IoT powered technology product, can bring global visibility to the supply chain. It can manage daily logistic operations easily. They are done by the automated guided vehicles (AGVs), telematics systems that help boost the logistic processes' accuracy and speed, minimizing human intervention. WMS optimises all the inventory tasks and procedures in the system.

The M2M technology streamlines and monitors the automation process of a warehouse. One doesn't need to watch manually how the orders are processed. Mixed with WMS, the latest M2M systems can now control all the warehouse equipment, which is essential to order fulfillment processes. M2M provides actionable insights to make better decisions in terms of accuracy in information, leads to demand forecasting that helps one predict when to deliver a product.

Voice technology is one of the most effective picking methods used in logistics management. The VWMS technology uses voice recognition and speech synthesis enabling workers to communicate within WMS. Spoken commands are given for picking, receiving, putting orders, and other warehouse shipping functions.

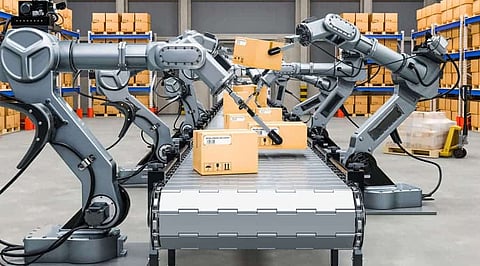

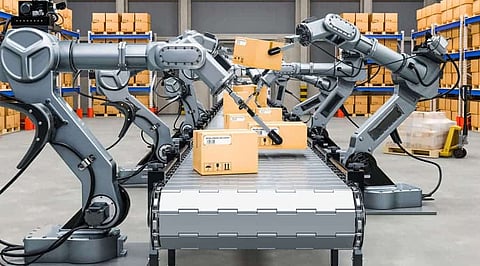

Smart robots help in the movement, sorting, and storage of inventory in the warehouse. As a manager of the warehouse, one should pick robotics technology that suits the requirement.

The description of the technologies mentioned above is not the end of technological intervention while dealing with numerous chores within the cycle of warehouse management. There are many other technologies than AI, ML, and robotics available in the market. There are pick-by-vision technology, use of drones, specific labour management system software, and many more. One should consult experts to decide which technologies suit the warehouse requirement, environment, facilitating smoother operations, and supply chains.

Join our WhatsApp Channel to get the latest news, exclusives and videos on WhatsApp

_____________

Disclaimer: Analytics Insight does not provide financial advice or guidance. Also note that the cryptocurrencies mentioned/listed on the website could potentially be scams, i.e. designed to induce you to invest financial resources that may be lost forever and not be recoverable once investments are made. You are responsible for conducting your own research (DYOR) before making any investments. Read more here.